*Stainless Steel Automatic Animal Feed Mill

The customer has a medium-sized pig breeding base. With the continuous expansion of the breeding scale in recent years, the output of the existing small-scale feed production equipment can no longer meet the growing demand. Recently, the customer ordered a 5tons stainless steel automatic batching feed mill plant from our company. The equipment is currently installed.

Product features: The main equipment of this animal feed mill is made of stainless steel, which is anti-corrosion and reduces maintenance costs for customers. The automatic metering oil injection pump can quickly measure the oil required for each batch of feed instead of manual, and evenly spray and add it during the feed stirring overshoot.

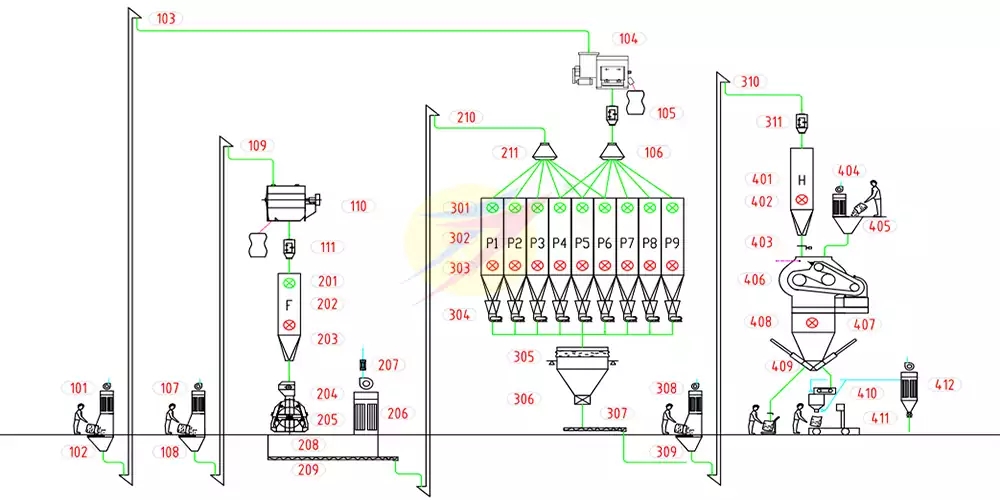

The animal feed mill process is composed of batching, lifting, storage, crushing, mixing, and finished product storage. The process is continuous and reasonable, and the operation and maintenance are convenient.

There are two structural forms of medium and large feed production lines: integral steel frame type and floor type. The overall steel frame layout is compact, and the shape is beautiful and elegant; the floor type is easy to use and maintain. Large and medium-sized automatic batching feed production equipment adopts computer automatic batching, with good batching accuracy, high degree of mechanization and automation.

*10 TPH poultry feed premix production line in South Africa

Project site: South Africa

Capacity: 10 tons per hour

Application: layers, broilers, pigs, birds, etc.

Main Raw material: grains, corn, protein, bone meal, vitamins, lysine, salt and minerals etc.

The customer has its own customer group of poultry farmers in South Africa, and invested in the construction of this fully automatic feed premix production line, which mainly sells chicken feed at different growth stages.

Our designers and process experts designed this feed production line according to the characteristics of the customer’s premix formula.

*3TPH Animal Feed Production Plant Project in Ghana

Project site: Ghana

Capacity: 2-3 ton/h ( 15,000 tons per year )

Application: Pig

Main Raw material: Corn, wheat, soybean meal, fish meal

Last year, a Ghanaian client planned to invest in a pig farm to produce his own pig feed. The customer found our animal feed production plant projects in other African countries through Google.

After communication, we recommend the customer to purchase the 320 model feed production line according to the size of the customer’s factory, the number of pigs, feed materials and other conditions.

The animal feed production plant adopts a vertical layout steel frame structure, including feed crushing, mixing, pelletizing, cooling, sieving, automatic packaging section, with grease adding and steam boiler system to meet production needs.

After in-depth communication, the customer was very satisfied with our feed mill plant design plan, and quickly paid the deposit. Our company immediately started order production, and with the assistance of engineers, instructed the customer to build the plant and the pit. After 45 days of intensive stocking, the order production was completed. , Send pictures and videos to the customer for inspection, the customer is very satisfied, and the balance payment is paid and the goods are shipped smoothly.

At present, the customer has completed the installation of the pig feed production line and is ready to start producing pig feed.

*1 ton animal feed processing machine in Vietnam

Project site: Vietnam

Capacity: 1-1.5 ton/h

Application: poultry and animal small feed factory

Final pellet: 4 – 8 mm

Main Raw material: Corn, soybean meal, bran, bone meal

Cost: 13000-20000 USD

1T/H-3T/H poultry and fish combined feed production line in Bangladesh

Project site: Bangladesh

Capacity: 3 tons of poultry feed and 1.5 tons of floating fish feed

Final pellet: 2-12 mm pellets

Main Equipment: feed hammer mill, aquatic feed extruder, double shaft paddle Mixer, feed pellet machine, pellet crumbler machine, cooling machine, packaging machine and and other auxiliary equipment, etc.

The 1t/h-3t/h poultry and fish combined feed production line project covers an area of 16*8*7 meters. The raw materials are corn, wheat, soybean meal, oil, additive and other mixtures.

Our company provides customers with flow charts, installation drawings, operating instructions, steel list, floor schematics and other materials, and dispatches technicians and installers to the local to guide the construction. After 50 days of hard work, the feed mill plant was completed and successfully debugged and started to produce feed pellets.

10TPH poultry and livestock feed plant in Oman

Project site: Oman

Capacity: 10TPH poultry and livestock feed plant

Final pellet: 3-12 mm feed pellet

Main Equipment: Feed hammer mill, mixing machine, Ring Die Feed Pellet Machine, Counterflow Cooler, Screw Conveyor, Bucket Elevator, Pulse Dust Collector, Cyclone Dust Collector, Silos, etc.

The customer is a local feed manufacturer, which provide different size pellet with packagae to many farms and agents. He need more capacity to expand his business, so he chose 10t capacity per hour.

We arranged two engineers to help the customer install the production line, it takes about 30 days for installation and testing. The 10TPH livestock feed plant works very well now.

If you have any interest on our animal feed plant, please contact us now for quotation.

*8TPH animal feed manufacturing plant installed in Senegal

Project site: Senegal

Capacity: 8TPH animal feed manufacturing plant

Final pellet: 8-12mm feed pellet

Main Equipment: Feed hammer mill, mixing machine, Ring Die Feed Pellet Machine, Counterflow Cooler, Screw Conveyor, Bucket Elevator, Pulse Dust Collector, Cyclone Dust Collector, Silos, etc.

The customer plan to manage the feed pellet business, there are many animal farm and other poultry farms, with experienace of buying pellets from other farm,he found the suitable feed mill plant from our website and purchased at once. After 2 months he installed this new production line with the manual and drawing we sent to him.

Then he sent two pictures as a feedback gift.

This feed production line produces enough feed pellets and he will find more farms to sell his fodder.

In the near future, he will creat a new feed brand to expand the local market.

*6TPH animal feed processing plant installed in Greece

Project site: Greece

Capacity: 6TPH animal feed processing plant for animal feed production

Final pellet: 8-12mm feed pellet

Main Equipment: Feed hammer mill, mixing machine, Ring Die Feed Pellet Machine, Counter flow Cooler, Screw Conveyor, Bucket Elevator, Pulse Dust Collector, Cyclone Dust Collector, Silos, automatic packing machine, etc.

The customer need automatic packing system, max 4 workers operation only, other are automatic working. We confirmed flow chart, installation drawings, pit drawings and operating instructions, finally the customer agreed this plan and confirmed this is he need.

In the near future, he will create a new feed brand to expand the local market.

Please contact us if you want to know more information about our poultry feed plant.

5TPH livestock animal feed plant feedback from Oman

Project site: Oman

Capacity: 5TPH livestock animals feed plant

Final pellet: 3-12mm feed pellet

Main Equipment: Feed hammer mill, mixing machine, Ring Die Feed Pellet Machine, Counterflow Cooler, Screw Conveyor, Bucket Elevator, Pulse Dust Collector, Cyclone Dust Collector, Silos, etc.

The customer is a local feed manufacturer, which provide different size pellet with package to many farms and agents. He need more capacity to expand his business, and has already bought one 10tph production line before.

We arranged one engineers to help the customer install the animal feed plant, it takes about 25 days for installation and testing. The production lines works very well now.

If you have any interest on our animal feed plant, please contact us now for quotation.

售前客服

售前客服