Wood pellet mill

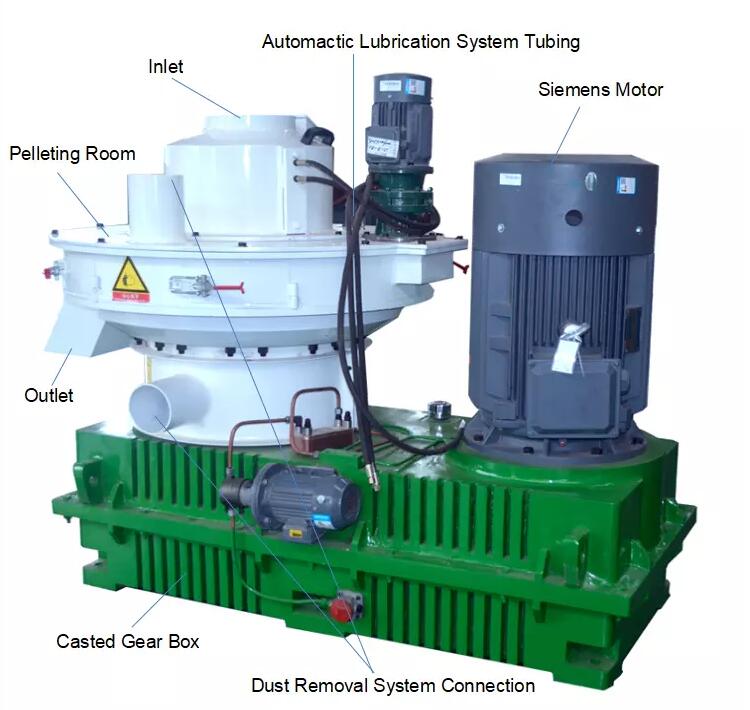

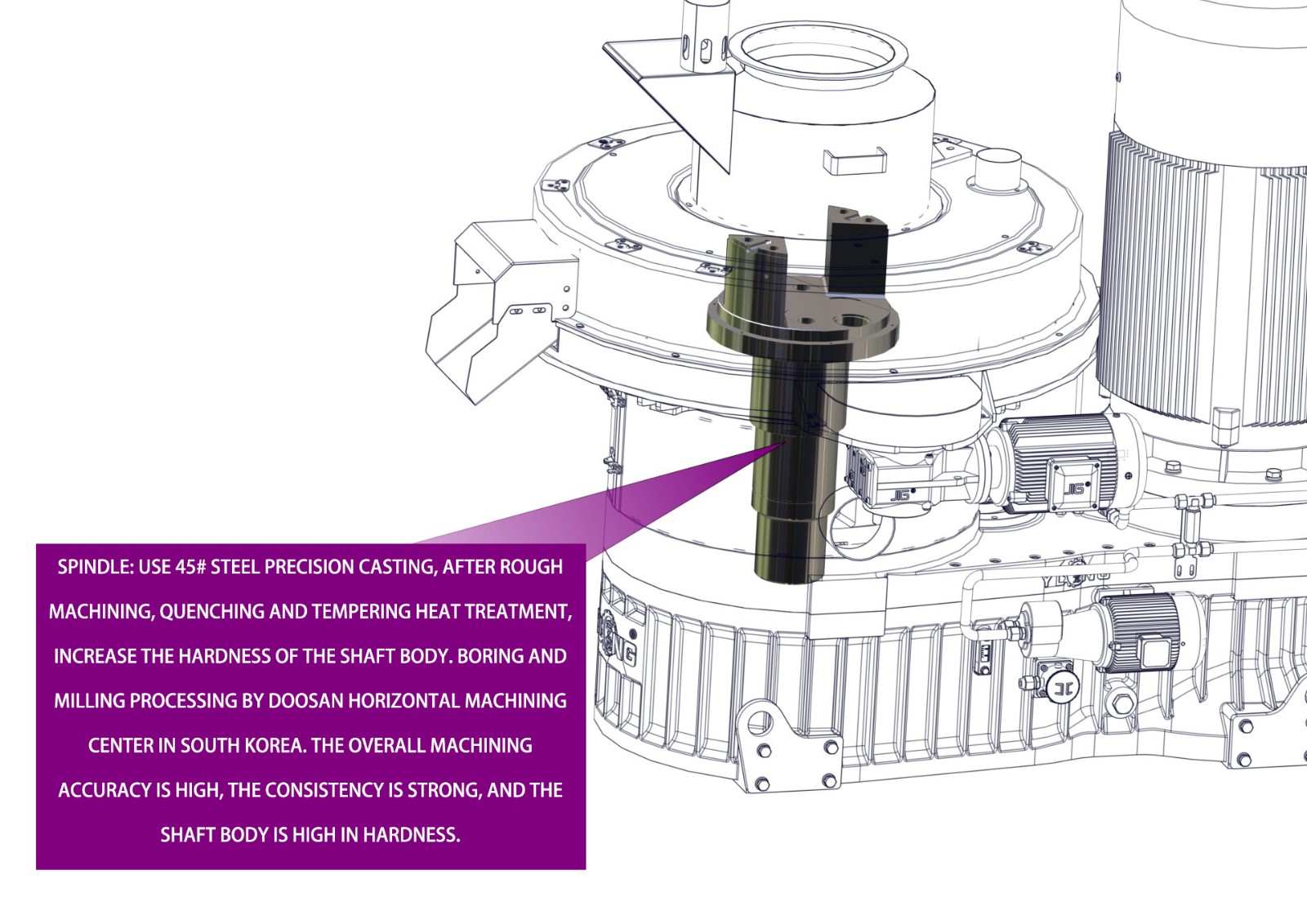

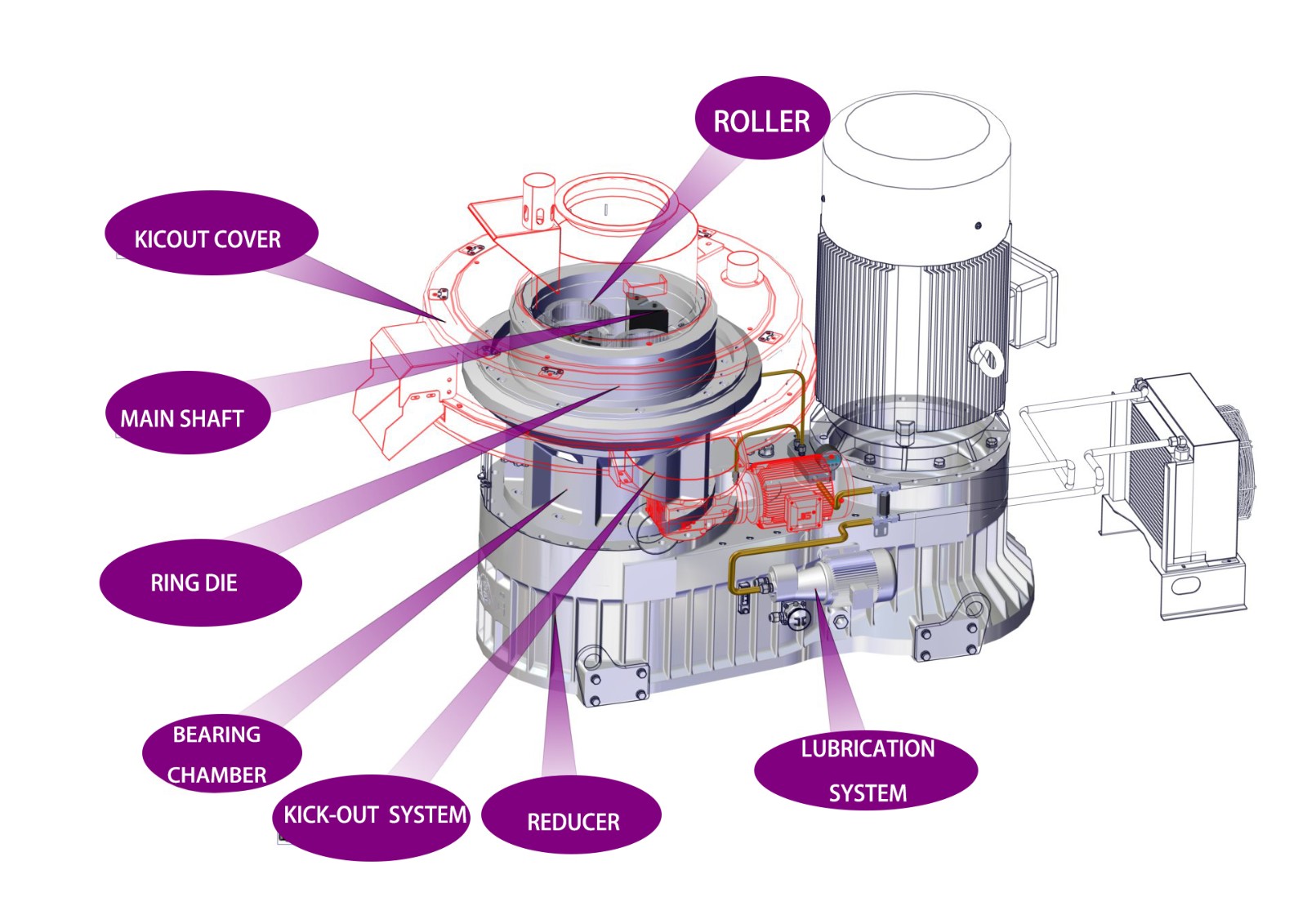

Our wood pellet mill details: All pellet presses are developed to give low production costs and high-quality pellets to make owners competitive in both private and industrial markets. A.Five characteristics 1. Vertical feeding, directly in place. 2. Die is static, rollers rotary; materials are evenly distributed around, because of centrifugal force. 3. Double-layer die. Two layers both can be used independently so the machine reduces the cost; What’s more, two layers of the die also can be used at the same time, in this way, the efficiency has been improved greatly, high capacity and save energy. 4. Ring die and vertical structure are good for cooling the pelletizing room. 5. Independent and frequency conversion discharge device can ensure the rate of pellet formation.

What kinds of material need for Vertical ring die wood pellet mill 1.Wood log:First use wood chipper convert wood log to wood chips ,if wood chips moisture >20%,We should add a dryer to dry the wood chip until moisture <15% . 2.Wood chips: Wood chips with moisture >20%,We should add one dryer to dry wood chips until <20%. If Wood chips are dry ,moisture <15%,it can be crushed by hammer mill directly,then it comes out as sawdust ,sawdust can make pellet directly; 3.Sawdust: Moisture >20%,need dry until moisture<15%,if sawdust size <5 mm,then make pellet directly.. 4.Palm fiber and EFB: Further crushed until size <1 mm,dried until moisture <15%. 5.Rice husk :Without hammer mill, when moisture <15% can make pellet directly. 6.Straw:Further crushed All of those material shall get size <8 mm,moisture <15%,easy to make good pellet by wood pellet machine. spare parts 6-8 mm pellet Include wood pellet,palm fiber pellet,EFB pellet,rice husk pellet,straw pellet,etc.